Introduction

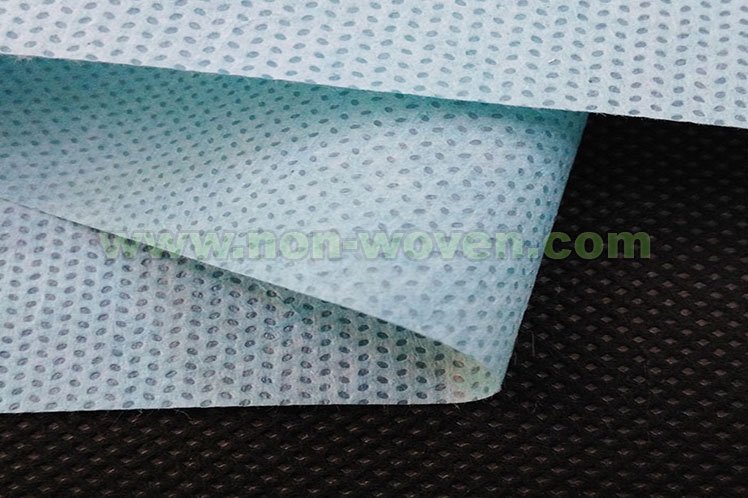

The non woven elastic fabric is a type of fabric that is made from interlocking fibres that are held together by a chemical or mechanical process. This type of fabric is often used in the manufacturing of clothing, upholstery, and other textiles.

The non woven elastic fabric has several benefits over other types of fabrics. It is more durable, breathable, and resistant to bacteria and mold. It is also more resistant to wrinkles and static.

The non woven elastic fabric is an ideal choice for a variety of applications. It is frequently used in the medical industry, as it is able to meet the strictest sterilization standards. It is also used in the food industry, as it can withstand high temperatures and is non-toxic.

Keep reading to learn more about the non woven elastic fabric and its many benefits!learn more(wikipedia)

Origins of the non woven elastic fabric:

The non woven elastic fabric is a relatively modern fabric that was developed in the early 20th century. It was initially created for upholstery and mattress covers. However, the fabric has evolved since then and is now used in the manufacturing of clothing, furniture, and other textiles. The development of the non woven elastic fabric was made possible through the use of specialized fabrics. These fabrics are made up of synthetic fibers that are bonded together using a chemical or mechanical process. The fibers are interlocking, which gives the fabric a certain stretch and flexibility.

Uses of the non woven elastic fabric:

The non woven elastic fabric is commonly used in the medical and food industries. In the medical industry, the fabric is often used for medical supplies, such as dressings, surgical gowns, and bandages. It is also used in the manufacturing of medical textiles, such as medical mattresses, pillows, and other specialty products. In the food industry, the non woven elastic fabric is often used in the production of food storage containers, food wraps, and other products. It is also used in the manufacturing of protective clothing, as it is able to withstand high temperatures and is non-toxic. The fabric is also used in the printing industry, as it is resistant to inks and other printing materials.

Properties of the non woven elastic fabric:

The non woven elastic fabric has several key properties that make it ideal for a variety of applications. It is durable, breathable, and resistant to bacteria and mould. It is also resistant to wrinkles and static. It is also lightweight and flexible, which makes it ideal for applications where comfort is paramount.

Advantages of the non woven elastic fabric:

The non-woven elastic fabric has several advantages over other types of fabrics. It is more durable, breathable, and resistant to bacteria and mould. It is also more resistant to wrinkles and static, making it easy to care for. The fabric is also lightweight and flexible, making it ideal for applications where comfort is paramount. It is also resistant to fire and will not melt when exposed to high temperatures, making it ideal for applications where fire safety is important. The fabric is also highly resistant to puncture and tearing, making it ideal for applications where durability is a must.

Disadvantages of the non woven elastic fabric:

Despite its many advantages, the non woven elastic fabric also has a few drawbacks. It is prone to stretching and shrinking, so it must be handled with care. It also requires more maintenance than other types of fabrics and can be difficult to dye. Additionally, the fabric is not biodegradable, so it must be responsibly disposed of.

Conclusion:

The non woven elastic fabric is a versatile and durable fabric that is used in the manufacturing of clothing, furniture, and other textiles. It is made up of interlocking synthetic fibers that are bonded together using a chemical or mechanical process. The fabric has several properties that make it ideal for a variety of applications. It is durable, breathable, and resistant to bacteria and mould. It is also lightweight and flexible, making it ideal for applications where comfort is a key factor. The fabric does have a few drawbacks, but these can be easily mitigated with proper care and maintenance.