Non-Woven Cotton Fabric: Definition, Manufacturing Process, Application Fields, and Development Trends

Definition of Non-Woven Cotton Fabric

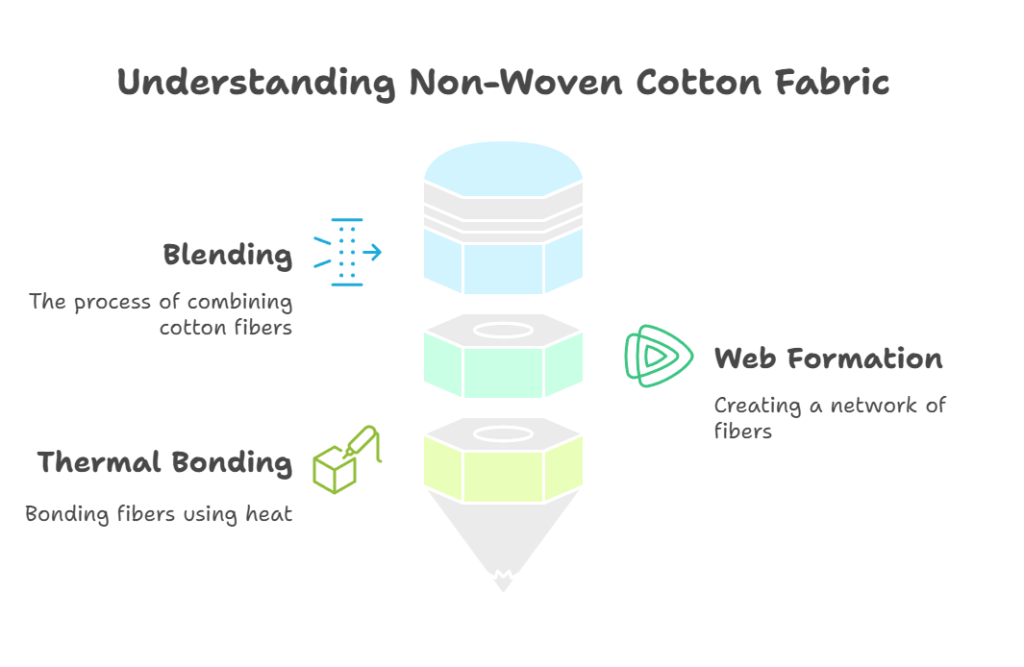

Non-woven cotton fabric, the name itself sounds like a piece of modern industrial magic. It doesn’t require traditional spinning and weaving processes but is made primarily from cotton fibers through blending, web formation, and thermal bonding. This new type of textile material boasts many unique characteristics and advantages.

Characteristics of Non-Woven Cotton Fabric

Non-woven cotton fabric is lightweight, breathable, soft, and highly absorbent. Its unique structure gives it excellent elasticity and abrasion resistance, along with good tensile strength and tear resistance. These properties make non-woven cotton fabric stand out in many fields.

Uses of Non-Woven Cotton Fabric

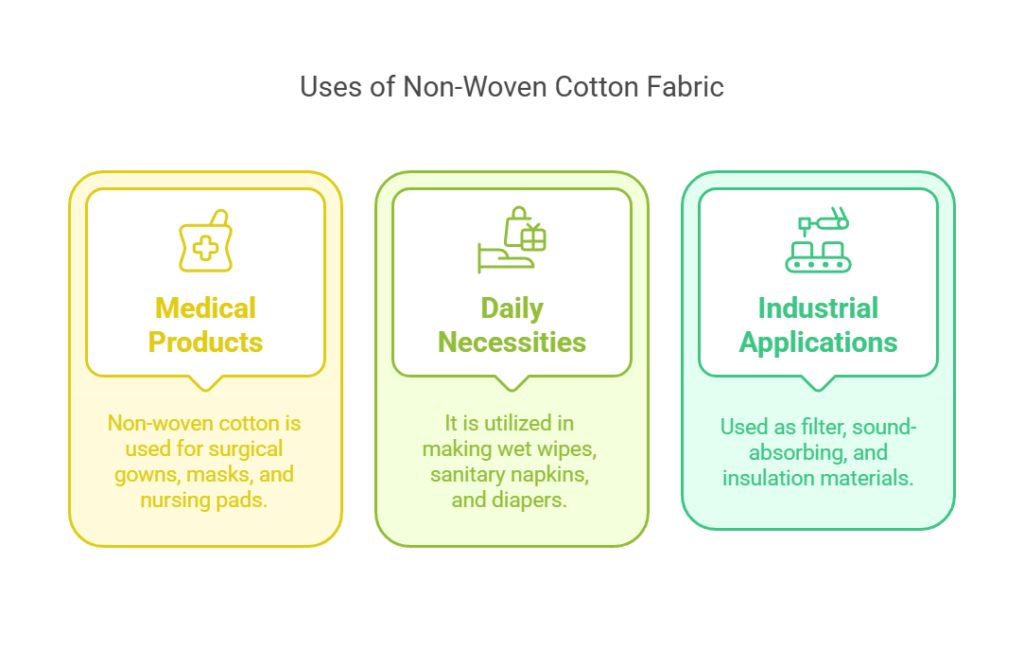

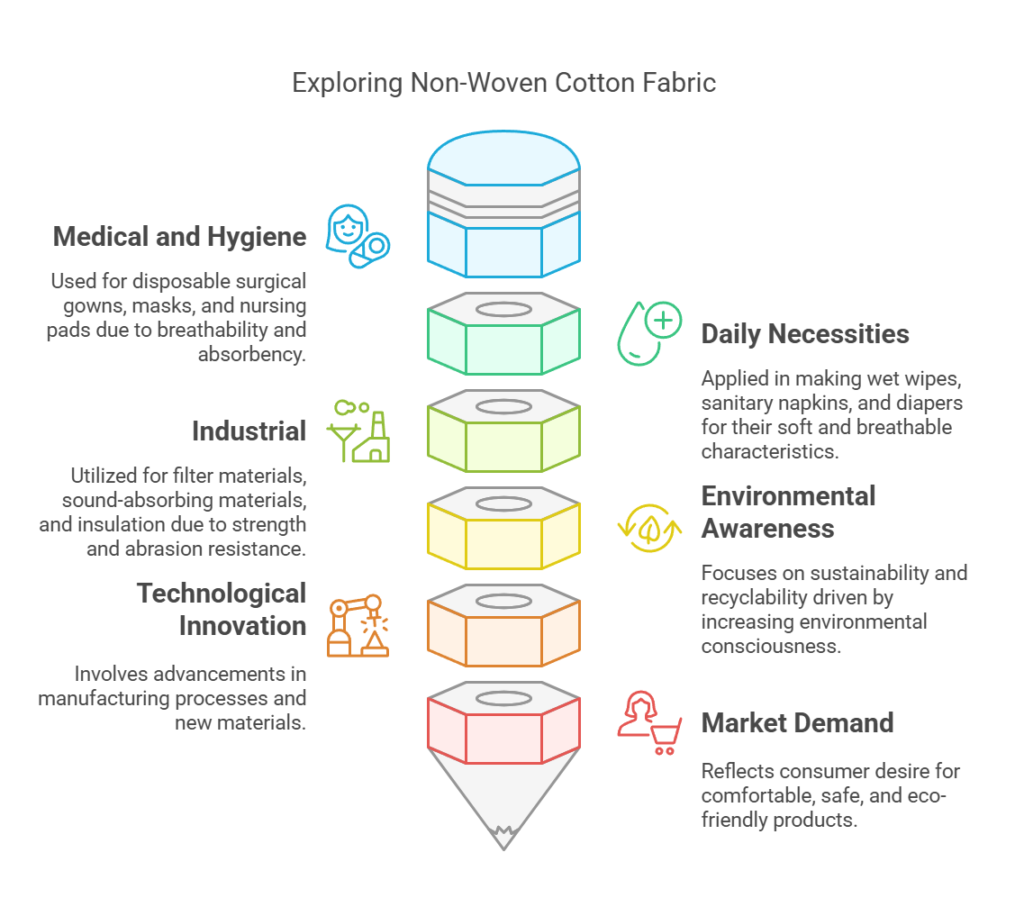

The uses of non-woven cotton fabric are extensive, ranging from medical and hygiene products to daily necessities and industrial applications. In the medical and hygiene field, non-woven cotton fabric is often used to make disposable surgical gowns, masks, and nursing pads. In the daily necessities field, it is used to make wet wipes, sanitary napkins, and diapers. In the industrial field, it is used as filter materials, sound-absorbing materials, and insulation materials.

Advantages of Non-Woven Cotton Fabric

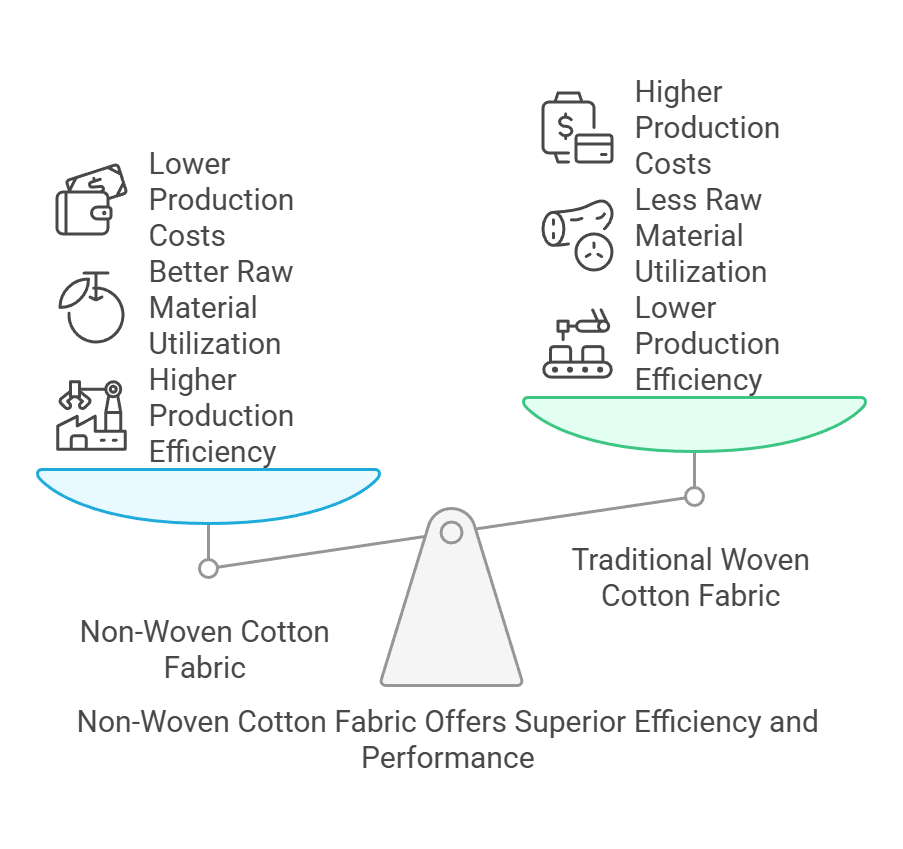

Compared to traditional woven cotton fabric, non-woven cotton fabric has higher production efficiency, better raw material utilization, and lower production costs. Its non-woven structure also provides excellent breathability and absorbency, making it widely applicable in the medical and hygiene and daily necessities fields.

Manufacturing Process of Non-Woven Cotton Fabric

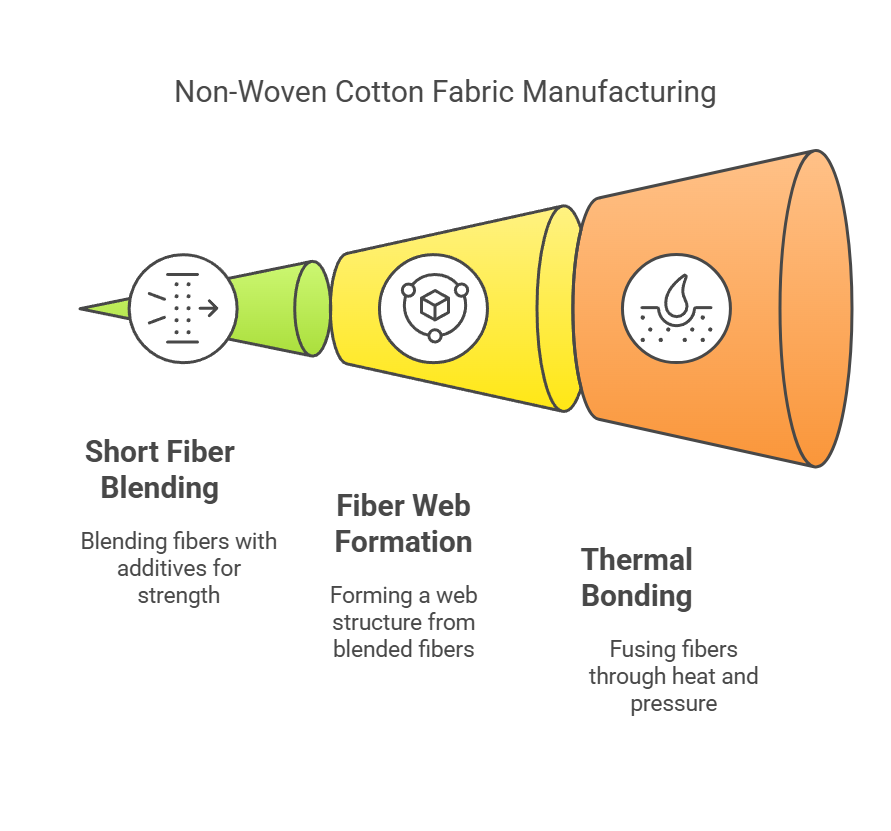

The manufacturing process of non-woven cotton fabric mainly includes three steps: short fiber blending, fiber web formation, and thermal bonding.

Short Fiber Blending

First, cotton fibers of different lengths are blended, and a certain proportion of recycled fibers or synthetic fibers are added to improve the uniformity and strength of the non-woven cotton fabric.

Fiber Web Formation

Next, the blended fibers are formed into a web through wet or dry methods, creating a uniform fiber web structure.

Thermal Bonding

Finally, the fiber web is heated and pressed using a thermal bonding process, causing the fibers to fuse together and form a strong and stable non-woven structure.

Application Fields of Non-Woven Cotton Fabric

Medical and Hygiene Field

In the medical and hygiene field, non-woven cotton fabric is often used to make disposable surgical gowns, masks, and nursing pads. Its good breathability and high absorbency make it widely used in medical and hygiene products.

Daily Necessities Field

In the daily necessities field, non-woven cotton fabric is used to make wet wipes, sanitary napkins, and diapers. Its soft and breathable characteristics make non-woven cotton fabric widely used in everyday life.

Industrial Field

In the industrial field, non-woven cotton fabric is used to make filter materials, sound-absorbing materials, and insulation materials. Its good strength and abrasion resistance make non-woven cotton fabric valuable in industrial applications.

Development Trends of Non-Woven Cotton Fabric

Development Driven by Environmental Awareness

As environmental awareness increases, non-woven cotton fabric, as a recyclable new material, is receiving more and more attention. In the future, non-woven cotton fabric will place more emphasis on sustainable development and environmental performance.

Development Brought by Technological Innovation

With continuous technological advancement, the manufacturing process of non-woven cotton fabric is constantly improving and innovating. The emergence of new materials and new processes will further drive the development of non-woven cotton fabric.

Development Led by Market Demand

As people’s demand for quality life increases, consumers’ need for comfortable, safe, and environmentally friendly products continues to grow. This will further drive the application and development of non-woven cotton fabric in the medical and hygiene, daily necessities, and industrial fields.

Conclusion

Non-woven cotton fabric, as a new type of textile material, has broad application prospects in the medical and hygiene, daily necessities, and industrial fields. With the increasing demand for quality life and enhanced environmental awareness, non-woven cotton fabric is expected to have a brighter development future.

Frequently Asked Questions

Q: What products are suitable for non-woven cotton fabric?

A: Non-woven cotton fabric is suitable for making sanitary napkins, diapers, nursing pads, face masks, medical masks, wipes, and more. Due to its good breathability and soft comfort, non-woven cotton fabric is also commonly used in bedding and household items.

Q: What are the advantages of non-woven cotton fabric?

A: Non-woven cotton fabric has good breathability, high absorbency, soft comfort, and abrasion resistance. Compared to traditional textiles, non-woven cotton fabric has a simple production process, low cost, and can be easily processed into various shapes and specifications.

Q: What is the manufacturing process of non-woven cotton fabric?

A: The manufacturing process of non-woven cotton fabric generally includes fiber preprocessing, blending, opening, web formation, pre-curing, and final shaping. Among these, web formation is the most critical step, where fibers are formed into a web structure through wet, dry, or a combination of both methods.

Q: What is the difference between non-woven cotton fabric and textiles?

A: Non-woven cotton fabric is made by forming fibers into a web structure, whereas traditional textiles are made by weaving yarn. Therefore, non-woven cotton fabric does not require spinning and weaving processes, has high production efficiency, and is cost-effective.