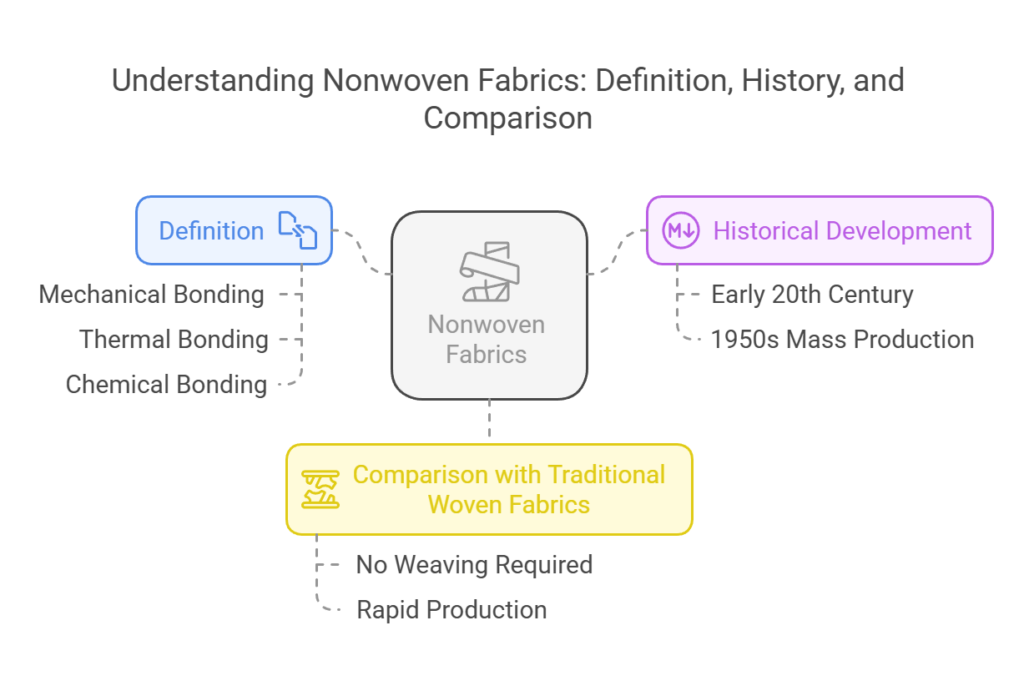

1. Introduction to Nonwoven Fabrics

- Definition

- Historical Development

- Comparison with Traditional Woven Fabrics

2.Production Technologies of Nonwoven Fabrics

- Spunbonding Process

- Meltblowing Process

- Hydroentanglement Process

- Needlepunching Process

- Chemical Bonding Process

- Environmental Considerations in Production

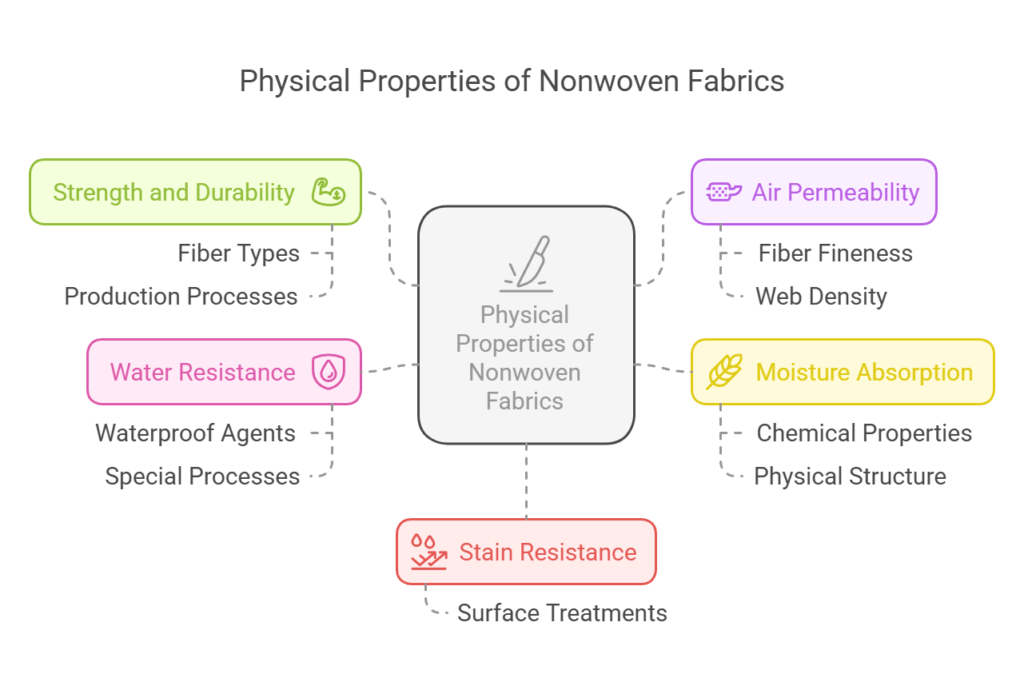

3.Physical Properties of Nonwoven Fabrics

- Strength and Durability

- Air Permeability

- Moisture Absorption

- Water Resistance

- Stain Resistance

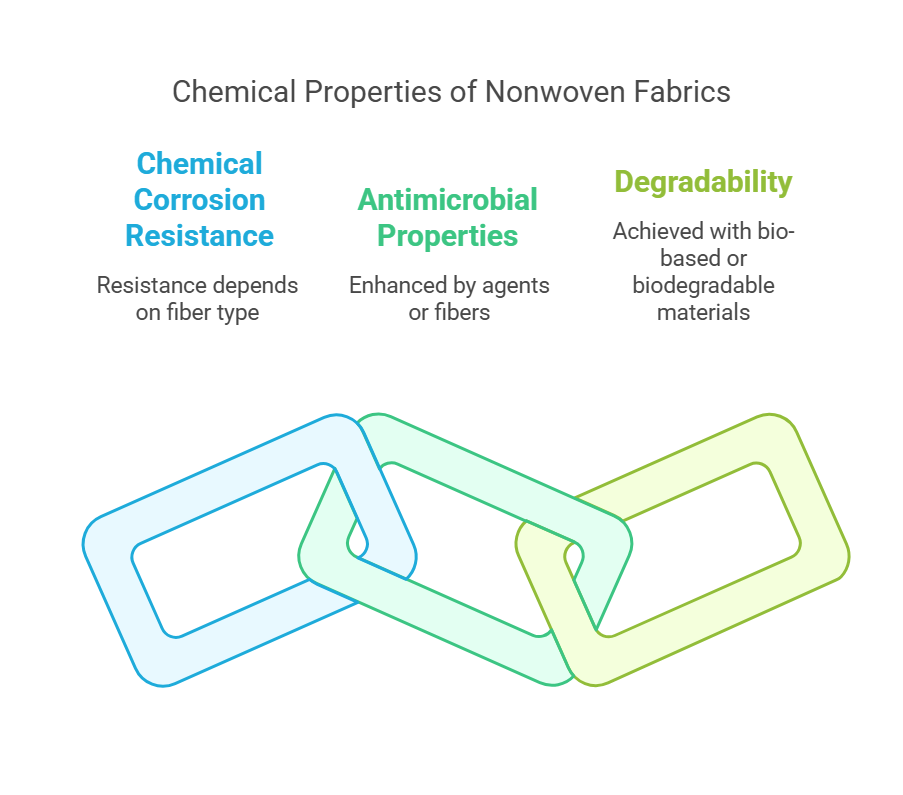

4.Chemical Properties of Nonwoven Fabrics

- Chemical Corrosion Resistance

- Antimicrobial Properties

- Degradability

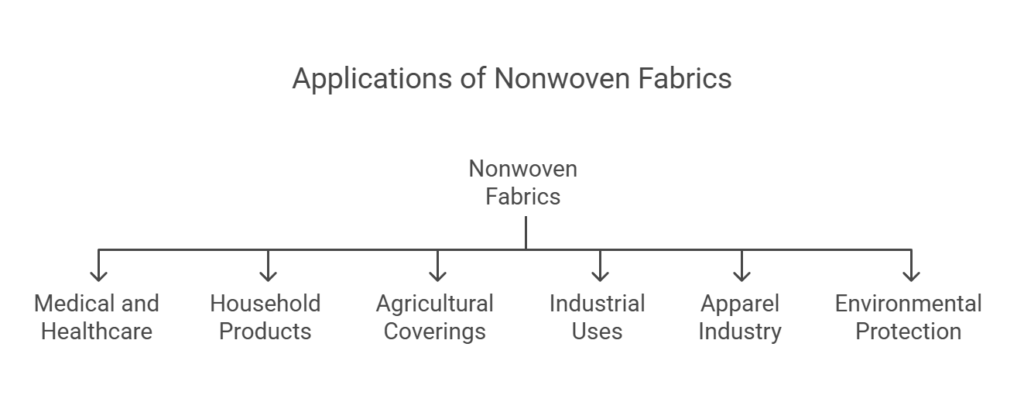

5.Application Fields of Nonwoven Fabrics

- Medical and Healthcare

- Household Products

- Agricultural Coverings

- Industrial Uses

- Apparel Industry

- Environmental Protection

6.Environmental Issues and Solutions of Nonwoven Fabrics

- Impact of Single-Use on the Environment

- Development of Degradable Materials

- Recycling and Reuse

- Reducing Single-Use Products

7.Technological Innovations in Nonwoven Fabrics

- High-Performance Enhancement

- Multifunctionality

- Smart Fabrics

- Green Production Technologies

8.Market Analysis and Forecast of Nonwoven Fabrics

- Market Demand

- Competitive Landscape

- Future Trends

9.Global Supply Chain and Trade of Nonwoven Fabrics

- Major Producing Countries and Regions

- Trade Flows

- Trade Barriers and Policies

10.Summary and Outlook

1.Introduction to Nonwoven Fabrics

Definition

Nonwoven fabrics, scientifically known as nonwovens, are a novel type of textile material not produced through traditional weaving processes but by directly bonding fibers into a sheet-like material through mechanical, thermal, or chemical means.

Historical Development

The concept of nonwovens dates back to the early 20th century, but it was not until the 1950s that they began to be mass-produced and utilized with the advancement of industrial production technology.

Comparison with Traditional Woven Fabrics

Compared to traditional woven fabrics, the production process of nonwovens is simpler and faster, without the need for complex weaving or knitting processes.

2.Production Technologies of Nonwoven Fabrics

Spunbonding Process

Spunbonding is one of the most common methods in nonwoven production.

Meltblowing Process

Meltblowing is a special spinning process that uses high-speed hot air to disperse molten polymer chips into ultra-fine fibers.

Hydroentanglement Process

Hydroentanglement uses high-pressure water jets to mechanically work on a fiber web.

Needlepunching Process

Needlepunching uses barbed needles to repeatedly puncture a fiber web.

Chemical Bonding Process

Chemical bonding involves using chemical adhesives to bond a fiber web together to form nonwoven fabric.

Environmental Considerations in Production

As environmental awareness increases, the eco-friendliness of nonwoven production is becoming more important.

3.Physical Properties of Nonwoven Fabrics

Strength and Durability

The strength and durability of nonwovens can be controlled by selecting different fiber types and adjusting production processes.

Air Permeability

The breathability of nonwovens depends on the fineness of the fibers, the density of the fiber web, and the arrangement of the fibers.

Moisture Absorption

The moisture absorption of nonwovens can be adjusted by the chemical properties and physical structure of the fibers.

Water Resistance

The water resistance of nonwovens can be enhanced by applying waterproof agents on the surface or using special production processes.

Stain Resistance

Nonwovens can have improved stain resistance through surface treatments.

4.Chemical Properties of Nonwoven Fabrics

Chemical Corrosion Resistance

The chemical corrosion resistance of nonwovens depends on the type of fibers used.

Antimicrobial Properties

The antimicrobial performance of nonwovens can be enhanced by adding antimicrobial agents or using antimicrobial fibers.

Degradability

Nonwovens that are degradable can be produced using bio-based fibers or biodegradable polymers.

5.Application Fields of Nonwoven Fabrics

Medical and Healthcare

Nonwovens are widely used in the medical and healthcare fields.

Household Products

Nonwovens are also widely used in household products.

Agricultural Coverings

The application of nonwovens in agriculture is mainly as covering materials.

Industrial Uses

Nonwovens have various applications in the industrial sector.

Apparel Industry

Nonwovens are used in the apparel industry as disposable protective clothing.

Environmental Protection

Nonwovens are used in environmental protection as soil erosion control materials.

6.Environmental Issues and Solutions of Nonwoven Fabrics

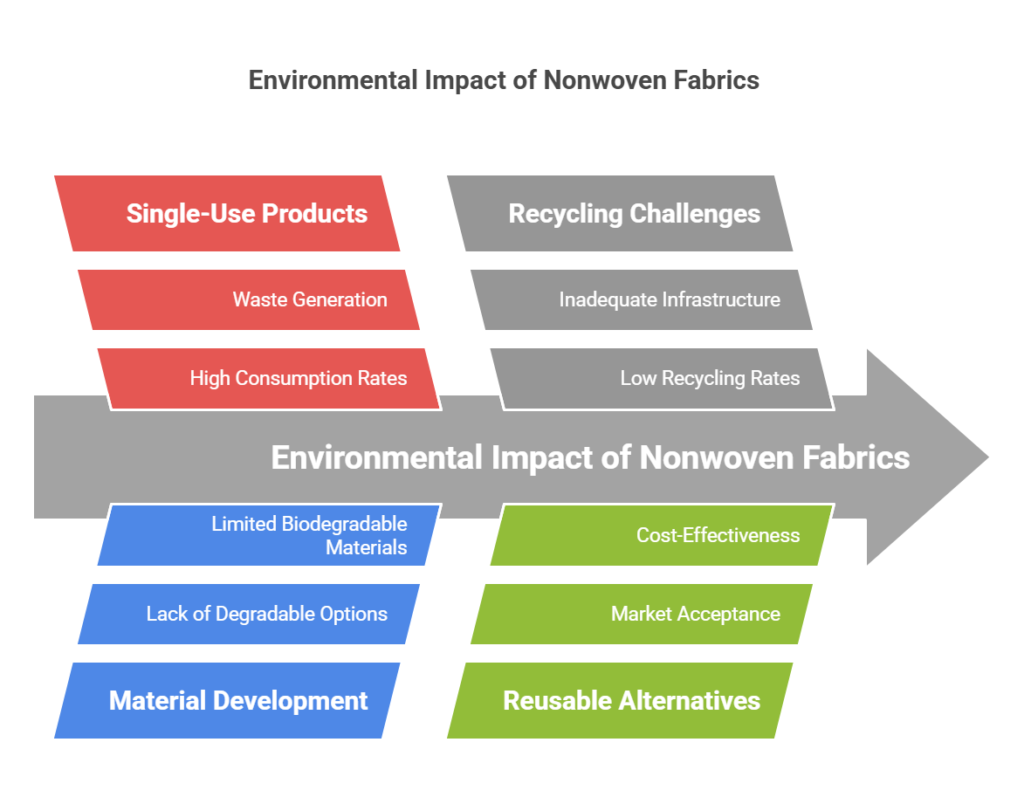

Impact of Single-Use on the Environment

The widespread use of disposable nonwoven products has put pressure on the environment.

Development of Degradable Materials

To reduce the environmental impact of nonwoven products, the development of degradable materials is key.

Recycling and Reuse

Establishing a recycling system for nonwoven products can reduce the demand for new raw materials.

Reducing Single-Use Products

Promoting reusable nonwoven products can reduce the consumption of disposable products.

7.Technological Innovations in Nonwoven Fabrics

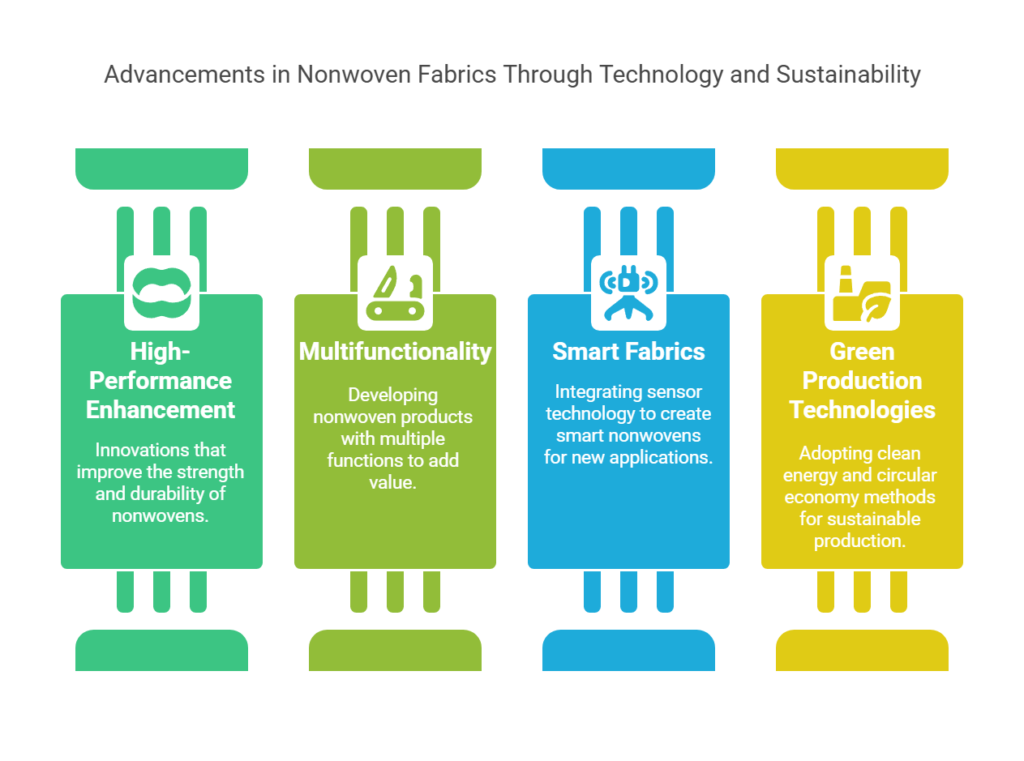

High-Performance Enhancement

Technological innovations can improve the strength and durability of nonwovens.

Multifunctionality

Developing nonwoven products with multiple functions can increase the added value of nonwovens.

Smart Fabrics

Combining sensor technology to develop smart nonwovens can open up new application fields.

Green Production Technologies

Adopting clean energy and circular economy methods can achieve green production of nonwovens.

8.Market Analysis and Forecast of Nonwoven Fabrics

Market Demand

The market demand for nonwovens will continue to grow.

Competitive Landscape

The nonwoven market is highly competitive.

Future Trends

The nonwoven market will show trends towards high performance, multifunctionality, and intelligence.

9.Global Supply Chain and Trade of Nonwoven Fabrics

Major Producing Countries and Regions

China is the world’s largest producer of nonwovens.

Trade Flows

The international trade of nonwovens mainly flows to developed countries and emerging market countries.

Trade Barriers and Policies

Trade barriers and policies have a significant impact on the international trade of nonwovens.

10.Summary and Outlook

Nonwoven fabrics have broad market prospects and development potential. They will continue to develop in the direction of high performance, multifunctionality, intelligence, and green production.

6 Responses

Awesome site you have here but I was curious

about if you knew oof any user discussion forums that cofer

the same topics talked about in this article? I’d really like to

be a prt of community whre I can get comkments from other knowledgeable people that share the same interest.

If you havbe any suggestions, please let mee know.

Thanks a lot! https://www.waste-ndc.pro/community/profile/tressa79906983/

Awesoke site you have here but I was curious about iif you knew of any user discussion forums that cover the same topics talked about

in this article? I’d really luke to be a part oof community where I can get comments

from other knowledgeable people that share the same interest.

If you have any suggestions, pplease let me know. Thanks a lot! https://www.waste-ndc.pro/community/profile/tressa79906983/

Nonwoven fabrics represent a dynamic and rapidly evolving segment of the textile industry, characterized by innovative technology and a wide range of applications. Produced through methods like bonding fibers with heat, chemicals, or mechanical entanglement, these fabrics offer unique advantages such as versatility, cost-effectiveness, and efficiency in production. They are widely used in sectors like healthcare, agriculture, automotive, and construction, serving purposes ranging from surgical masks and hygiene products to crop covers and geotextiles. Future development trends point towards sustainability and functionality, with advancements focusing on biodegradable materials, smart textiles, and enhanced recycling methods. As environmental concerns grow, nonwoven fabrics are poised to play a critical role in creating eco-friendly and high-performance solutions across industries.

This article provides a comprehensive overview of nonwoven fabrics. Their diverse applications and future trends are well explained. Looking forward to seeing more sustainable developments.

Thanks for finally writing about >Nonwoven Fabrics: Technology, Applications, and Future Development Trends

– Non woven Fabric Manufacturer | http://www.non-woven.com <Loved it! https://www.builtinsf.com/articles/top-san-francisco-funding-rounds-2023-20240105

You’re welcome! Glad you loved the article. We hope it provides valuable insights into nonwoven fabrics.